|

Axle repairing quality control card system can realize the automatic read and input of the only axle marking information and other relating production information; it shares with HMIS information and reduces the workload of manual read and input; it realizes the match of material flow and information flow and mutual card control; it can also improve the card control of repairing work. It can avoid the mismatch of the information of material flow, card flow and information flow in their parallel and independent process and it can also avoid the oversight of the repair and detection and ensure the correctness of the wheel set expense.

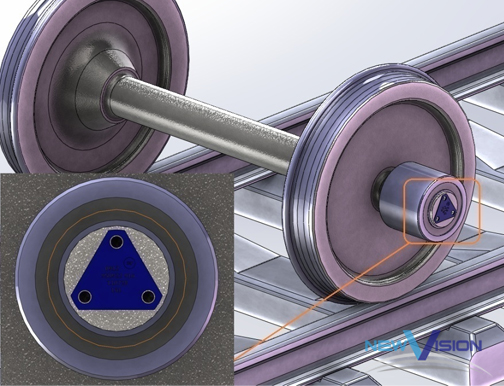

Sketch map of hard wares installation |

|

1. It can realize an automatic mark of bearings marking board and automatically upload to HMIS bearing location machine system.

3. It can make a mutual control of the inter-process of the bearings repair lines and realize the card control of information flow to material flow. |

|

This system adopts hand-hold image collecting device and image analysis technology. It can realize an automatic identification and input of bearings ends and marking boards and then share with HMIS. Finally it can realize the card control of bearings repair lines procedures. This system is at an experimental stage at present. The experimental result shows that it can realize the automatic input and mutual card control of material, card and information flows. It can avoid the oversight of bearing repair and detection. The experimental results are as follow:

Sketch map of detection location

Design sketch of automatic identification |